The LHC Run 2 ended on December 3, see the corresponding news. The current experiment will be largely dismantled and an almost completely new detector constructed during the two-year-long shutdown: a new LHCb will be born in 2021. The major fraction of LHCb’s sub-detectors will be replaced or upgraded during this shutdown. Last week about 500 members of the collaboration celebrated the end of the first stage of the experiment with the detector in its original form and the beginning of construction of a new detector. There were memorable sessions reminding members of the collaboration how the ideas of the first dedicated beauty experiment at the hadron collider were born and developed as well as on the history of different sub-detector construction.

They were followed by a fantastic party with amazing number of artists giving terrific musical performances, accompanied by video1, video2 and a slide show presenting images of the old detector and preparations for the installation of a new one. The image shows a musical ensemble playing “A Requiem for LHCb” during the celebration.

The construction of the new upgraded detector will profit from the most recent technological developments. LHCb physicists and engineers have been assisted in their efforts by excellent companies that have collaborated closely with LHCb and their contributions have been crucial in ensuring the successful upgrade of the experiment. The LHCb collaboration selected three outstanding companies, Kuraray, Europractice and Advacam, for LHCb Industry awards and presented these at a special ceremony which took place during celebration.

The images above show the celebration speech given by the Collaboration Board chairperson Valerie Gibson and the spokesperson Giovanni Passaleva and the presentation of the Industry Awards to the winners.

The Kuraray company delivered 12 000 km of scintillating plastic fibre for the LHCb Scintillating Fibre Tracker (SciFi) detector. The fibre is in principle a product available in Kuraray’s catalog, however, LHCb’s technical requirements in terms of attenuation length, light yield and geometrical quality significantly exceeded their standard specifications. The company had to improve production and environmental parameters and invest in measurement and quality control equipment. The stable quality of the product over the full delivery period was excellent, the photo and video shows the successful quality tests being performed at CERN.

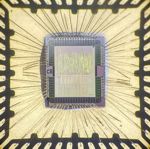

Europractice helped to design and produced the CLARO ASIC, a 8-channel amplifier/discriminator for single photon counting with multi-anode photomultiplier tubes. The ASIC, an Application-Specific Integrated Circuit, is an integrated circuit customized for a particular use, rather than intended for general-purpose use. The CLARO is designed to sustain high rate, up to 40 Mhits/s per pixel, with a low power consumption, and it is one of the main building blocks of the LHCb RICH upgrade. Europractice provided access to the software tools needed for ASIC design, and to the silicon foundry for prototyping and production. Nearly 100k chips were produced in total according to the specifications in terms of speed, power consumption and radiation tolerance, and these fulfill the requirements of the LHCb RICH upgrade. The images shows the CLARO ASIC.

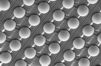

Advacam developed a novel thinned ASIC bump bonding technique for the Upgrade of the Vertex Locator of the LHCb detector. The company had a very collaborative approach to the R&D and prompt, large scale delivery of devices in full conformity with tender. LHCb very much appreciated the close collaboration of the company, with weekly meetings and feedback on all aspects of project. The excellent quality control achieved was particularly impressive. The image shows the interconnection bumps of the VeloPix ASIC.

A very busy period starts now. Members of the collaboration will continue to analyse Run1 and Run2 data and, at the same time, finalise construction and then install the new detector. The road towards new discoveries continues.