The LHC Run 2 ended a year ago. The LHCb experiment has been largely dismantled and an almost completely new detector is under construction in these very days: a new LHCb will be born in 2021. Almost all LHCb’s sub-detectors will be replaced or upgraded during the ongoing LHC shutdown and the new upgraded detectors will profit from the most recent technological developments. LHCb physicists and engineers have been assisted in their effort by excellent companies that have collaborated closely with LHCb and their contributions were crucial to ensure the successful upgrade of the experiment. The LHCb collaboration selected this year four outstanding companies, 3D Systems, Automation NV, LETI-3S and SOMACIS for the LHCb Industry Awards, and presented awards to these at a special ceremony which took place during the plenary collaboration meeting taking place this week at CERN. The images below show the awarded industry teams together with LHCb spokesperson and technical coordinator as well as LHCb physicists and engineers collaborating directly in the corresponding projects – the Kuraray team received this year the 2018 Award.

3D Systems produced the thin 3d-printed titanium bars with embedded cooling channels for the SciFi Tracker of the LHCb Detector. The challenge was to realize cooling pipes with a very complex shape in a tight space, very thin walls for thermal conductance combined with very tight mechanical tolerances (50 microns flatness), divided in subsections to minimize the effect of different thermal expansion coefficients and having an effective gluing surface. The scintillating-fibre tracker, SciFi, will be placed behind the dipole magnet of LHCb. The scintillating fibres emit light when a particle interacts with them and the tiny amount of emitted light is collected by silicon photomultipliers (SiPM) that convert it to electrical signals. The SiPMs are operated at low temperatures, about -40°C, and are therefore attached to the cooling bars as seen in the image.

Automation NV is responsible for the design, manufacturing, and installation of the new LHCb Data Centre (image). The company developed an innovative and very cost-effective cooling system based on a combination of adiabatic and indirect free-air cooling. An important part of the project is the cable management with 19 000 long-distance fibres and hundreds of inter-module connections. The new Data Centre will allow LHCb to implement a novel scheme of the data acquisition system. During Run 1 and 2 the event rate was filtered down to 1 MHz with the help of fast electronics, using comparatively simple algorithms to select the most interesting events. Those events were then processed in a dedicated computer farm, located underground close to the detector; this allowed additional, more sophisticated selection criteria to be applied using software. For Run 3 and beyond, this will change radically: the fast electronics will be removed and the whole detector will be read out at the full LHC pp collision rate of 40 MHz. This will allow the whole selection to be done in software in the new Data Centre located at the surface, meaning that it can be much more precise and flexible.

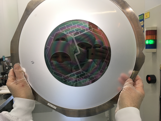

The team at Leti-3S developed new techniques to produce large silicon cooling plates with bi-phase CO2 circulating into micro-channels fabricated inside the plates themselves. The plates, just half a millimeter thick, will be used to cool the hybrid pixel sensors of the new LHCb VELO (Vertex Locator) detector. Leti developed a complex multistep microfabrication process, deploying supreme control of the channel dimensions, the strength of the wafer bonding, and the precise etching of the final pieces. The devices were produced on 8-inch silicon wafers, shown in the image, featuring two micro-channel cooling plates and smaller test structures. The new VELO will come as close as 5 mm to the proton beams and therefore will allow LHCb to localise precisely the points at which beauty and charm particles decay (read more and more).

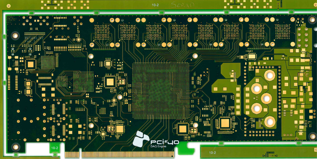

SOMACIS produced Printed Circuit Boards (PCB) for the large and sophisticated data acquisition electronic boards PCIe40. The PCBs (image) are complicated due to a large number of components being interconnected. Some of them have a very dense matrix of connections over the 14 layers of PCBs. Layers are not symmetric, 35 µm of copper on one side and 70 µm on the other one. Some planes carry current up to 60 A with high speed signal up to 10 Gbit/s. The PCIe40 boards are essential elements of the new LHCb data acquisition system. The boards are located in the Data Centre and receive data through optical fibre links transmitting signals from the underground detector to the Data Centre at the surface at the 40 MHz rate. The boards are programmable and perform different tasks for different sub-detectors preparing data for further analysis in the computer farm.