The principle task of the tracking system is to provide efficient reconstruction of charged-particle tracks. These are used to determine the momenta of charged particles and to reconstruct Cherenkov rings in the RICH detectors.

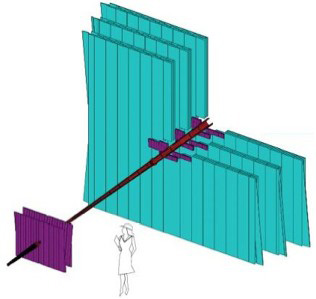

The main tracking system comprises four tracking stations: one station (“TT”) is located between RICH-1 and the LHCb dipole magnet, while the other three stations (“T1-T3”) are located over 3 metres between the magnet and RICH-2.

Two detector technologies are employed:

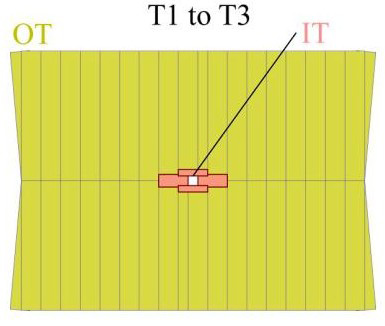

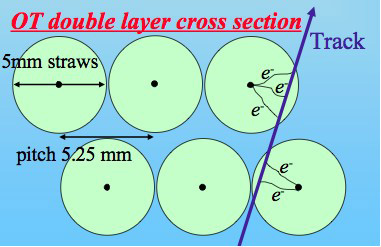

1) The Outer Tracker uses straw-tube drift chambers with 5 mm cell diameter and covers the largest fraction of the detector sensitive area in stations T1-T3. The largest station will cover a sensitive area of 600 cm x 490 cm.

2) The Silicon Tracker uses silicon microstrip detectors with a strip pitch of approximately 200 μm. It comprises the entire TT station and a cross-shaped area (the Inner Tracker) around the beam pipe in stations T1-T3. Its total sensitive surface is approximately 11 m².

The Silicon Tracker

The silicon tracker comprises two detectors – the Trigger Tracker (TT) and the Inner Tracker (IT), both of which use silicon microstrip detectors with long readout strips and with strip pitches of about 200 μm.

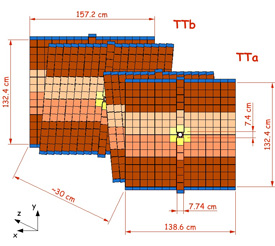

The TT is a 150 cm wide and 130 cm high planar tracking station that is located upstream of the LHCb dipole magnet and covers the full acceptance of the experiment.

The IT covers a roughly 120 cm wide and 40 cm high cross-shaped region in the centre of three large planar tracking stations downstream of the magnet. Each of the four Silicon Tracker stations consists of four detection layers.

Silicon technology is expensive but offers a very fine spatial resolution. Therefore it is used only where the density of particles is high, which is mainly in the forward direction close to the beam pipe.

Charged particles passing through the detector displace electrons from their atomic shells, thereby creating an electric charge that can move freely in the detector volume. An electric field of a few hundred volts is applied across the detector volume to collect these electric charges on the electrodes, where they create an electric pulse that can be amplified and detected. The electrodes are finely segmented and by looking at which electrode has given a signal it is possible to determine where the particle has passed through the detector.

In total, the Silicon Tracker has some 270,000 readout electrodes and can measure the position of a particle to better than 0.05 mm.

Outer tracker

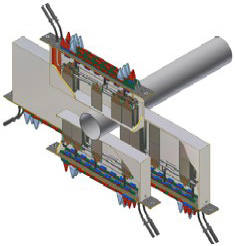

The design of the three Outer Tracker stations is modular. Each is built from 72 separate modules supported on four independently moving aluminium frames (18 modules per frame).

A module consists of two panels and two sidewalls, which form a mechanically stable and gas-tight box, and contain up to 256 straw tubes filled with a mixture of argon (70%) and carbon dioxide (30%) gas.

The straw tubes are arranged in two staggered mono-layers and are glued to the panels using a high-precision jig to accurately define the straw tube position and straightness. The panels are made of a Rohacell core reinforced by carbon skins. In addition, the inner panel side has an extra layer of a polyimide-aluminium laminate ensuring gas tightness and electrical shielding.

The straw tubes are wound from two layers of foil material. An inner layer of carbon-doped Kapton (Kapton XC) acts as a cathode for the collection of the positive ions. The outer layer, made of a polyimide-aluminium laminate, provides shielding and together with the anode wire forms a transmission line for the effective transport of the high-frequency signals. By application of a crimped contact on both layers of the straw tube walls, a good and reliable interface with the front-end electronics ground is ensured.

Straw tube technology has a coarser resolution (about 0.2 mm) than the silicon detectors but is much cheaper and therefore very well suited to cover the large areas of the tracking system where particle densities are not as high. The resolution is improved by measuring the drift time of the ionization.